Our robust project management goes beyond the standard steps you may be familiar with – system design, procurement, build, debug, factory acceptance testing and customer sign off.

Our process also ensures three key foundational goals are achieved:

IDS brands have industry-leading automation expertise. We have over four decades of experience building hundreds of automated pad printing, hot stamp and heat transfer systems ranging from simple semi-automated options to highly complex full automations.

Our robust project management, investment in cutting edge technology and considerable market-specific expertise allow us to provide automations tailor-made for optimal performance on your unique application.

The best possible solution is identified for the application at hand

Made possible by cutting-edge tools + superior engineering

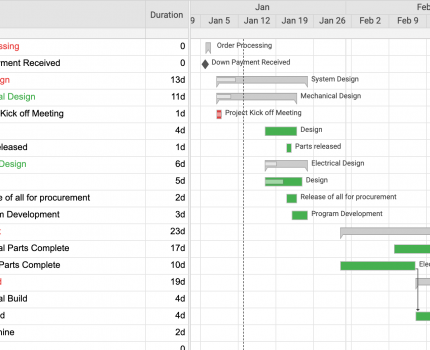

Customers see real time projects updates via Gantt charts on digital SmartSheets

Our engineers are highly skilled in analyzing a wide range of factors in order to present the best possible technology for a particular product decorating challenge.

Our engineers carefully consider:

Once an order is received, our team of mechanical, electrical, control engineering and parts handling experts get to work designing a precision solution for your unique application. Whether the automation is big or small – the unmatched expertise of our team combined with our investment in cutting-edge technologies allow us to design systems with market-leading efficiency and precision.

We listen carefully to our customers’ specific needs at each stage of development; from quoting through the final design review. Our proactive approach to customer communication ensures superior outcomes.