Heat Seal Process

Traditionally, the packaging industry has relied on metal seal heads, bars and platens for rigid and flexible packaging.

While metal is durable and tolerant to temperature, pressure and speed requirements, it is also non-flexible. This creates a narrow process window.

The result? Lower than expected production yields and unacceptable scrap rates!

Thermally conductive silicone rubber (capable of meeting temperature, pressure and speed requirements) was introduced as an alternative to metal more than 40 years ago for hot stamp decoration and the same approach is extremely effective for heat seal processes.

Silicone rubber dies, sheets, seal heads, rollers and seal bars provide compliance or “give” achieving complete coverage of surface variations ensuring reliable seals, higher production yields and reduced reject rates.

For more information, please visit

Americas: United Silicone

EMEA & Asia: CER

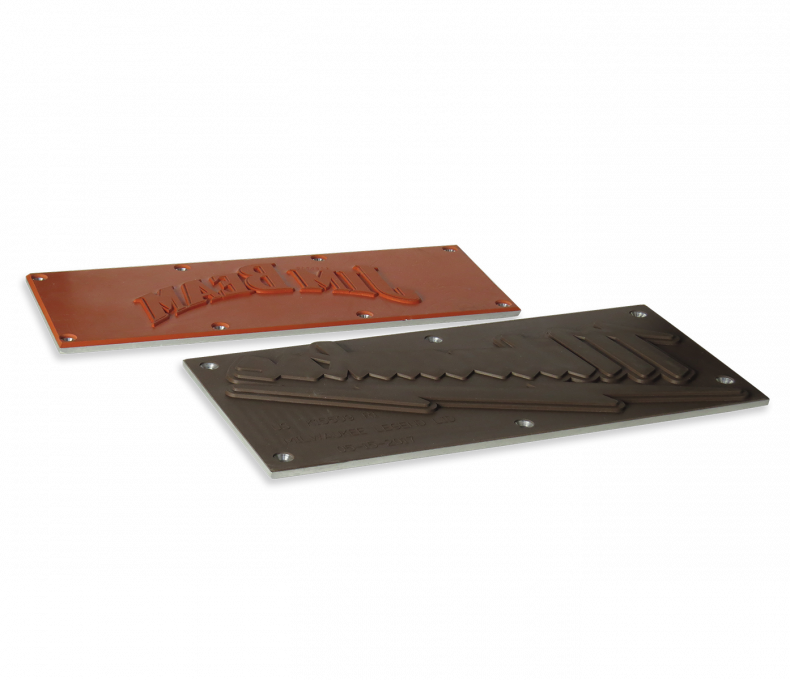

The powerful combination of metal and silicone tools working together is an efficient way to create higher yields and superior seals.

The silicone may appear at the top or the bottom of the assembly depending on part and machine geometries. Silicone can be used either in the holding fixture or in the seal head or bar.

Typically- thermally conductive seal bars (also referred to as “jaws”) are used for flexible packaging applications.

For rigid packaging applications- silicone is often used in the part holding fixtures. However, in some instances silicone seal heads can replace metal heads with a number of key performance advantages.

For more information, please visit

Americas: United Silicone

EMEA & Asia: CER