Industrial Product Decoration

IDS technology is widely used to apply branding, measurement, indicator, safety instruction, and certification information on a wide variety of electrical component applications.

- Print Durability

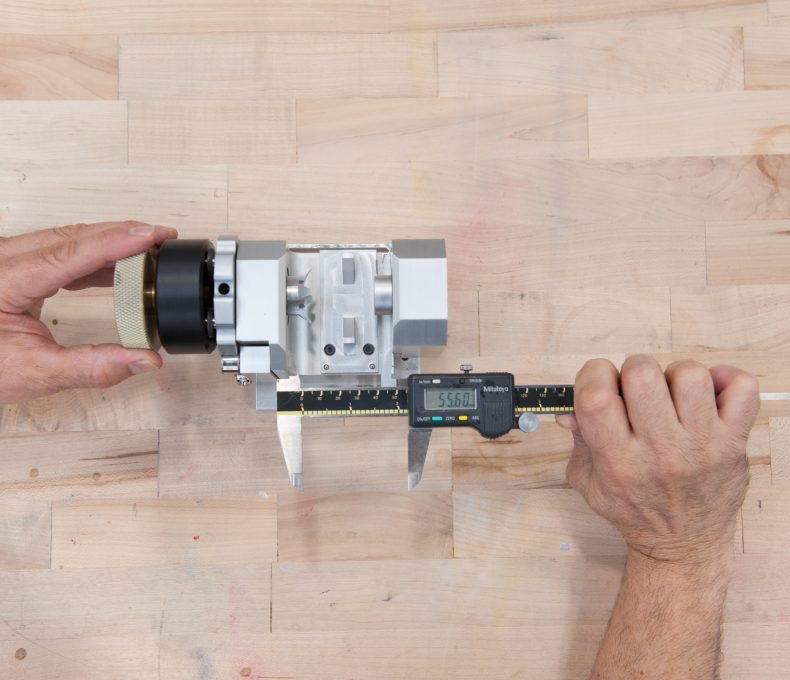

Most durable inks in the market provide decoration that is readable for decades. - Print Precision

Market-leading precision decoration on applications where even the slightest variation can be dangerous - Production Efficiency

Best-in-the-business at complex automations. We have you covered from simple manual systems through large automations requiring pre- and post-treatments, various colors, vision inspection and more

Applications

Precision Placement of Vital Information

We have experience applying branding, safety, voltage measurement, indicators and other decoration on switches and circuit breakers. We can print on two levels (top and bottom of switch) with a single pass – generating significant time savings.

Typical applications include:

- Switches (1 pole, 3, pole, 5 pole)

- Circuit Breaker Housing, Cases and Connectors

Our systems print safety and function indicators, branding, compliance certifications, serial numbers, model information and other elements on plugs and switches. As a global provider- we are familiar with plug variations in each country and we are capable of designing high-speed automation systems to support the decorating speed these applications often require.

Typical applications include:

- Plugs (wide variety of different shapes and sizes unique to each country or region)

- Switches (of all kinds including indicators, dimmers and more)

Electrical coil and thermostat decoration require precision performance to ensure indicators are precisely aligned for proper system performance. Furthermore, indicator decoration is often required on challenging conical shapes.

Typical applications include:

- Electrical Coil

- Thermostat Indicators

- Light Barriers

Decoration on tools must be carefully designed to be durable in even the most rugged of industrial environments. Decoration should be extremely abrasion resistant to tolerate vibration, dust, and dirt. IDS brands provide pad print, hot stamp and heat seal solutions that allow tool manufacturers and OEMs to add logos, safety indicators and other important information on their products.

Our custom tooling designs address the challenging contours, raised (aka “tipping”) or recessed decorating surfaces that are traditionally seen on Power Tool Housings. We also have decades of experience overcoming part to part variations often seen with extruded or soft-grip hand tool handles.

The resulting high-quality, durable decoration beautifully highlights the product brand or model.

Typical Applications Include:

- Corded & Cordless Tools Housings

- Hand Tools

IDS has a range of pad print, heat transfer and hot stamp solutions to provide durable, precision decoration on tool accessories and tool storage products.

We have developed innovative silicone dies and custom tooling specially designed to address the challenges inherent in decorating raised areas on both injection and blow molded tool carry/storage cases.

We also have expertise in numerous coating options associated with decoration of tool accessories like blades.

Typical Applications Include:

- Toolboxes / Tool Chests

- Cases for Drill Bits / Screwdriver Bits / Socket Sets

- Blades (circular, reciprocating, jig and hole saws)

IDS offers specialized solutions for decorating counter wheels. We know how to deliver durable print with superior weather, chemical and friction resistance. We can ensure precision registration without damaging a wheel. Our total solution (which includes specialized tooling) is capable of processing up to 3,200 pieces per hour.

Typical applications include:

- Gas Counter Wheels

- Water Counter Wheels