Automotive

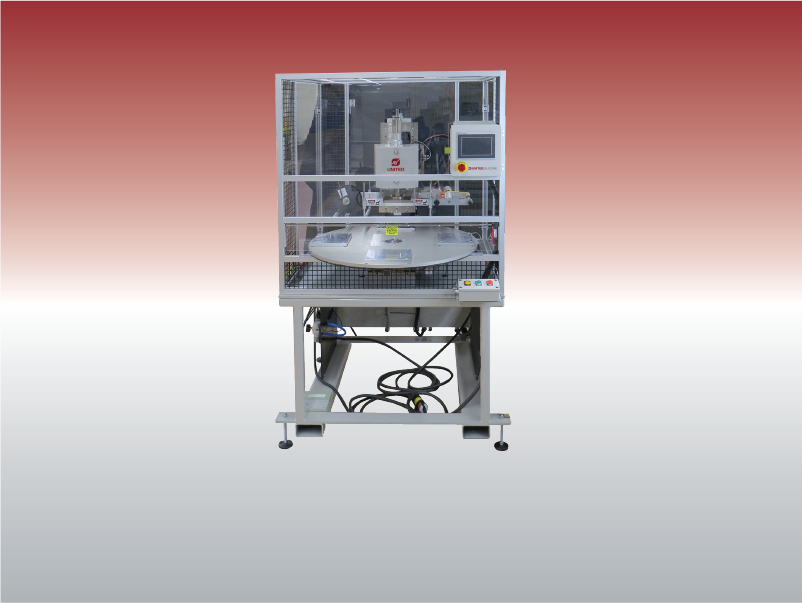

IDS brands provide hot stamp, heat transfer and pad print decoration on a wide variety of automotive products and components. We provide market-leading tight tolerance for even the most challenging automotive parts. Automotive brands, component/assembly manufacturers and automotive molding specialists trust IDS brands for:

- Product Decoration Systems – Stand Alone to Fully Automated

- All Tooling & Consumables

- Expert Automotive Adherence and Validation Services

Market Expertise

- Deep understanding of automotive market

- Pain points

- Decoration placement & durability requirements

- Industry trends

Superior Decoration

- Designed to meet needs for

- Easy changeovers

- Low scrap

- Consistent decoration even with challenging foils or substrates.

Turn-Key Systems

- Newest technology for part movement, safety and ease of use

- In-house die & tooling manufacturing for simplified production

Applications

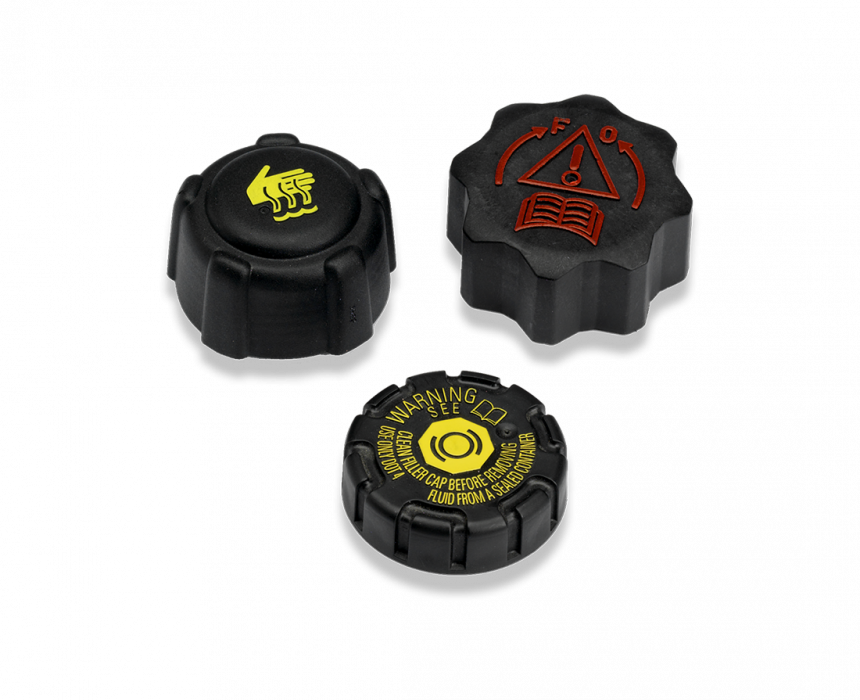

Durable, Precision Decoration on Automotive Parts

We understand the tight tolerance required for quality decoration and color matching on interior automotive parts. Our 40 years of experience can ensure smooth production flow and consistent quality.

Typical applications include:

- Knobs

- Controls

- Displays

- Gear/Shifter Plate

- Trunk Latches

IDS brands provide pad print, hot stamp and heat transfer decoration on a wide variety of exterior automotive parts. Our extensive artwork expertise stands out when tight tolerances or precise light diffusion requirements are present.

Typical applications include:

- Medallions/Badges

- Light Pipes

- Fuel Caps

- Light Lens Covers

- Concept/First Run Cars

- Tires/Mudflaps

- Exterior Trim/ Grills

- License Plates

We know how to navigate the tight tolerances, painted surfaces, unique part angles, and challenging foil requirements that often accompany dashboard product decorating. Our quality machines and tooling are engineered for superior printing of buttons, logos and shift bezels.

Typical applications include:

- USB/Sync Logos

- Dash Clusters

IDS pad print, hot stamp and heat transfer technologies are ideal for underhood automotive part decoration. Our systems provide consistently superior decoration that exceeds industry quality standards for tolerances and ink durability. Our turnkey systems can pretreat and cure parts in line for better product flow.

Typical applications include:

- Engine Covers

- Fill Caps

- Engine Covers

- Fill Caps

- Engine Belts

- Battery Housings