Medical Device Decoration

Learn more about our capabilities, common applications and dedicated products/services

IDS brands provide precision pad print, hot stamp and heat transfer decoration on a wide range of medical devices. Leading medical brand owners, component/contract manufacturers and small molders have relied on our medical product decoration expertise for over 40 years.

IDS brands have deep expertise in the specific challenges faced by the medical market.

We provide:

- Precision Image Quality (standard tolerance +/-0.005”)

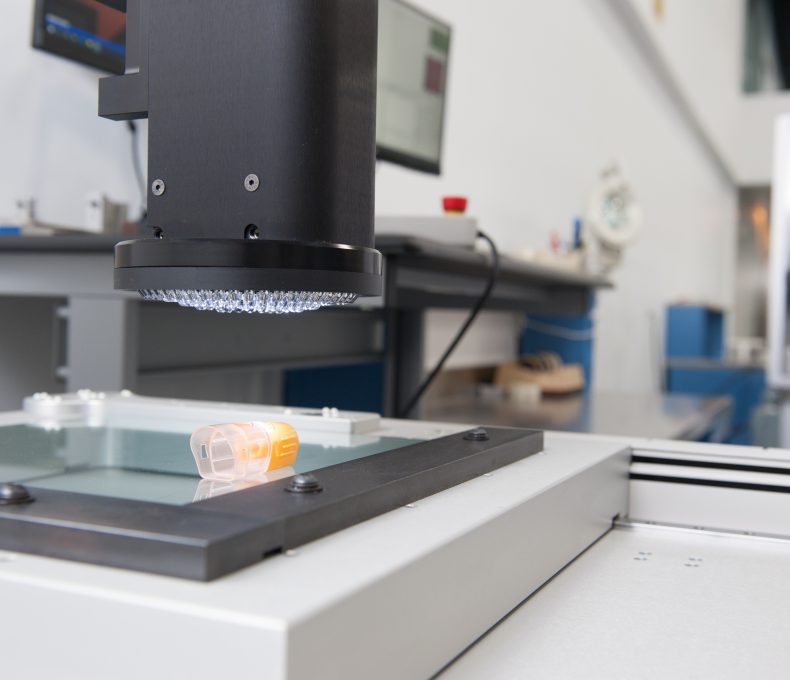

- Full Automation Support (partial to full turn-key solutions including integrated vision systems)

- Documentation and Validation Support (URS, FS, IQ, OQ, PQ)

- Total Process Support (systems, consumables, pre-treatment, and post-treatment equipment)

Total Solution For Medical Product Decoration

Equipment, consumables, vision systems, automation and validation support

IDS brands provide traditional and rotary pad print, hot stamp, and heat seal decoration as well as heat sealing on a wide array of medical device & component applications.

We provide equipment, consumables, and dedicated services to decorate medical devices for branding, functional deposition or identification marking purposes. Our sealing technologies are used for applications like the sealing of IV bags. We have proven solutions for multiple substrate types, shapes, and regulatory requirements.

Typical applications include:

- Medical Components

(medical housing/plastic housing, measuring wheels/disks, suture pouches) - Medical Devices

(infusion pumps, glucose meters, bottles/containers, biomedical devices) - Dental products

- Actuators / pump platforms / bottles

Placement of identification marking on syringes must be extremely precise for user safety. IDS brands provide pad print and hot stamp decoration for superior repeatability with industry-leading throughput.

Typical applications include:

- Standard disposable syringes

- Pre-filled syringes

- Safety syringes

- Auto injection devices

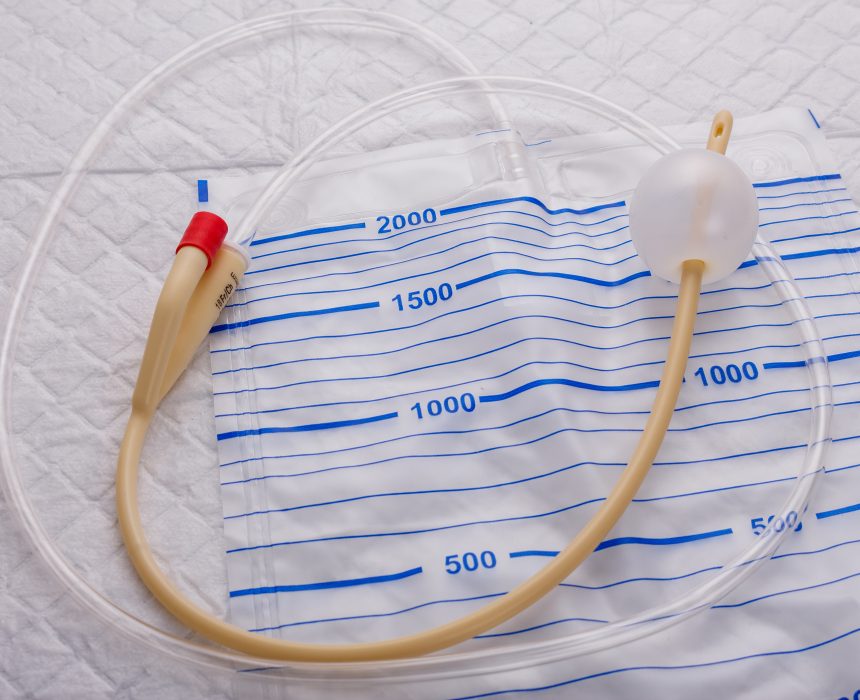

Catheter and medical tubing require decoration technology that can adapt to a wide variety of base materials, tube lengths, and French size diameters. IDS brands deliver both custom and standard solutions to meet these critical market needs.

Typical applications include:

- Catheters (6 French to 22 French diameter)

- Medical tubing (6 French to 22 French diameter)

New regulations requiring dosing tracking have led to unique decorating requirements. IDS brands provide proven solutions for highly repeatable, precise, quality decoration.

Typical applications include:

- Air Disk Wheels

- Cylinder Wheels